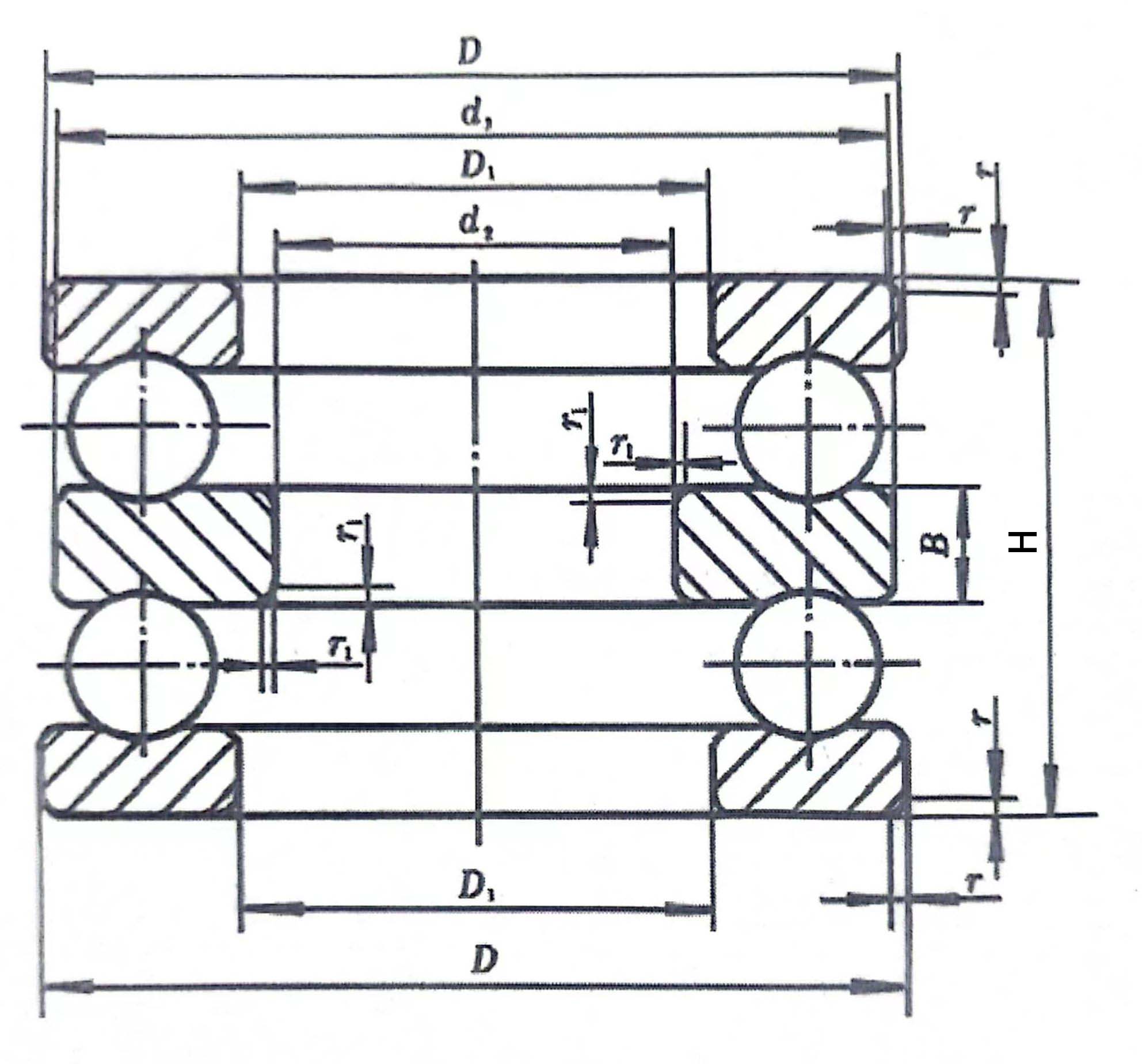

Double Direction Thrust Ball Bearings

Double direction thrust ball bearings are specialized bearings capable of withstanding thrust loads in both directions. They consist of spherical rollers and two bearing washers, with each bearing washer designed with grooves to accommodate the rollers. This design enables double direction thrust ball bearings to evenly withstand thrust loads in both directions, thereby achieving bidirectional support and balance.

Specifications- Material: Chrome steel, stainless steel, ceramic hybrid, plastic

- Precision: ABEC-1 to ABEC-9

- Size: Greater than or equal to 2mm bore dia.

- Cage: Stamped steel cage, solid cage

Double direction thrust ball bearings are characterized by their strong load-bearing capacity and flexible rotation, making them suitable for applications requiring even distribution of thrust loads in both directions, such as automotive transmissions, marine propulsion systems, hydraulic pumps, fans, and more.

How can bearing accuracy be distinguished?

Bearing accuracy levels are denoted as P0, P6, P5, P4, and P2, ranging from low to high precision. Here's a breakdown of these accuracy levels:

- P0: Applicable for rotational precision greater than 10 μm in bearing systems such as the speed-changing mechanism of ordinary machine tools, feed mechanism, speed-changing mechanism of automobiles, tractors, and other commonly used machinery.

- P6: Suitable for precision within 5-10 μm in bearing systems with rotational speeds of m or higher, such as the front support of an ordinary lathe using level 5 and the rear support using level 6.

- P4: Ideal for precision less than 5 μm in ultra-precision machinery with high rotational speeds, including precision coordinate boring machines, gear systems of precision grinding machines, and other precision machinery.

How to Choose a Bearing?

Bearing accuracy levels are denoted as P0, P6, P5, P4, and P2, ranging from low to high precision. Here's a breakdown of these accuracy levels:

- Understand the load requirements of bearings in your industry.

- Determine the rotational speed requirements for bearings in your industry.

- Identify the lubrication method suitable for your bearing needs.

What is the bearing load and load capacity?

Bearing load is typically defined as the reactive force exerted on the bearing by the components during use. When selecting the appropriate bearing for your application, it is crucial to first determine the bearing's load capacity.