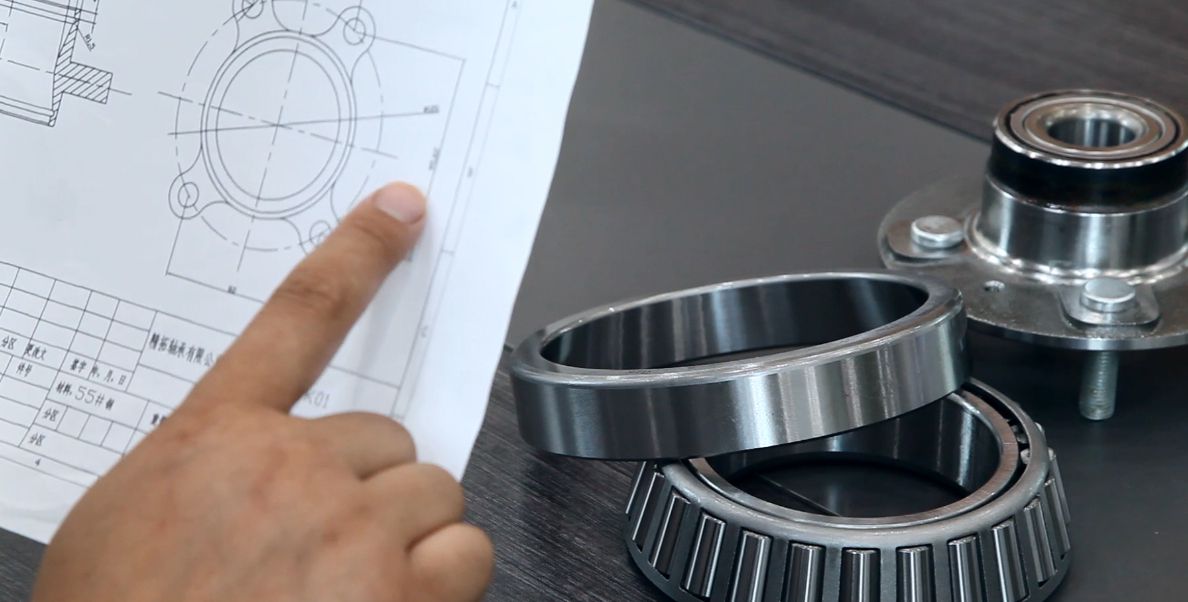

Our R&D center continuously conducts technological transformations and enhancements, resulting in the acquisition of numerous national invention patents. A unique heat treatment process is utilized through an energy-saving roller-type mesh belt resistance furnace automatic production line.

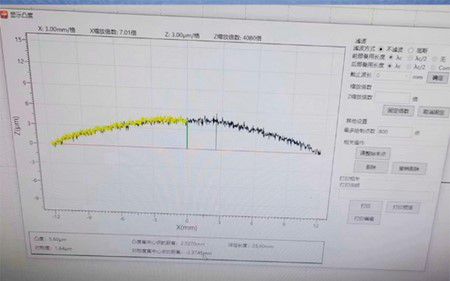

Currently, the precision levels of bearing reach P0, P6, and P5, and vibration values can achieve Z1V1, Z2V2, and Z3V3, making the bearing products highly favored in both domestic and international markets.