Forklift Bearings

The forklift bearing is a specialized bearing installed on the lifting mast of a forklift, guiding the forks to remain on the vertical track of the mast. The bearing is a crucial component of the forklift's lifting system. Specially designed forklift bearings can meet different requirements for lifting loads ranging from light to heavy capacities. They offer several advantages such as prolonging the lifespan of the forklift mast, reducing maintenance costs, simplifying mast structures, and enhancing operational stability.

Mast guide bearing has heavy section outer rings, serving as the rollers and guides for the forks (carriage) in the lifting and lowering motion along the mast channel. It is designed to fit the contour of the mast channel and can be made into dual hardness types when necessary. For forklifts handling super heavy loads, bearings with a guide and full complement rollers structure are ideal to use.

Forklift rolling bearings and forklift chain sheaves (chain pulley) come in various structures to meet the requirements of different applications.

-

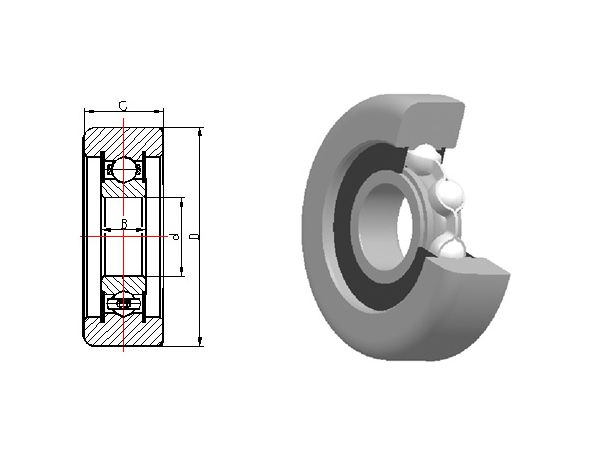

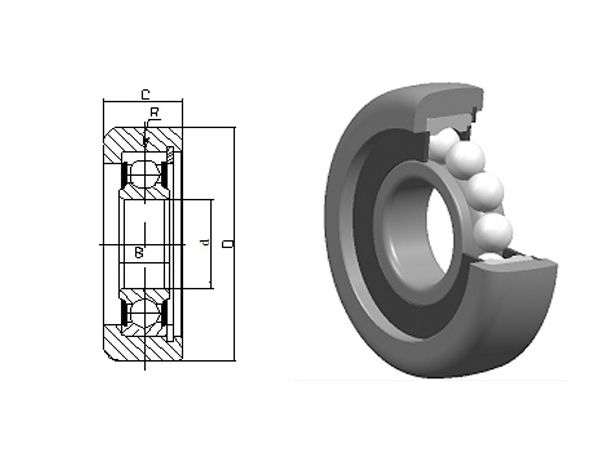

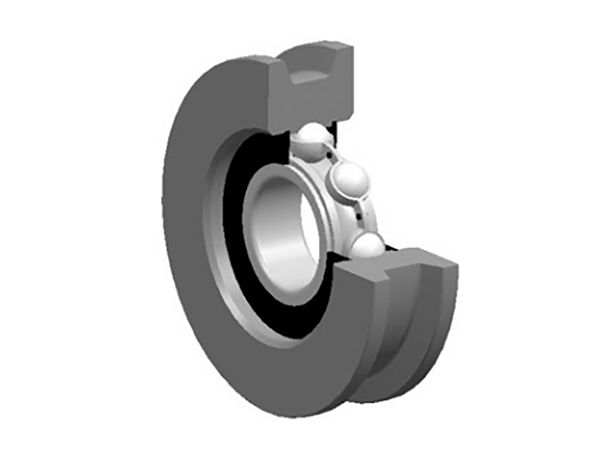

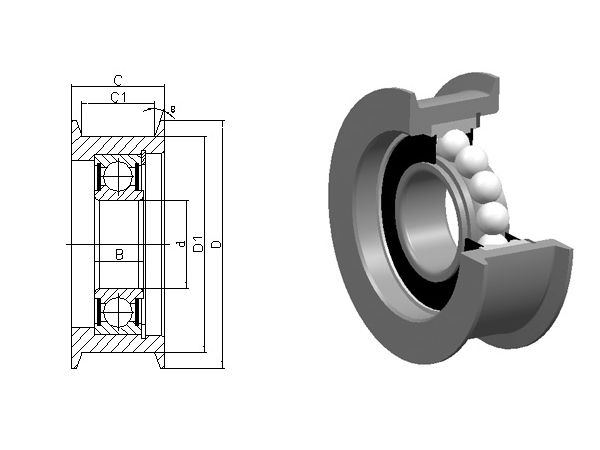

Single Row Ball Bearing Mast Guide BearingsPlease download the PDF for details.

Single Row Ball Bearing Mast Guide BearingsPlease download the PDF for details. -

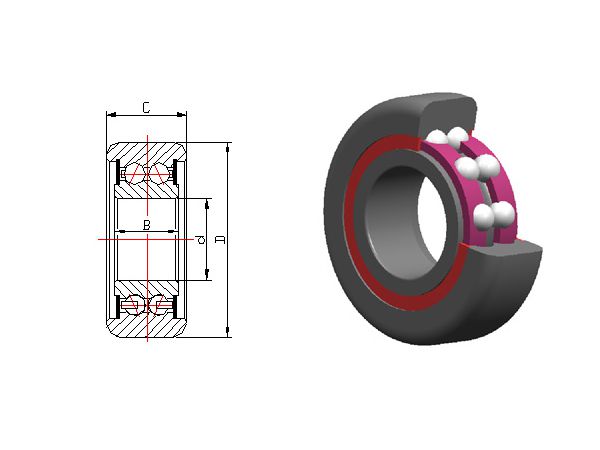

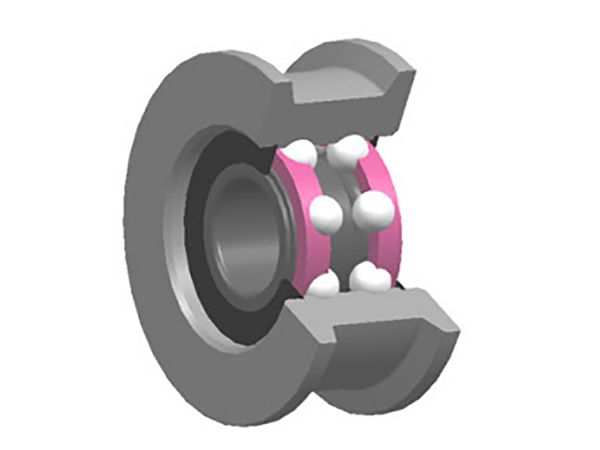

Double Row Ball Bearing Mast Guide BearingsPlease download the PDF for details.

Double Row Ball Bearing Mast Guide BearingsPlease download the PDF for details. -

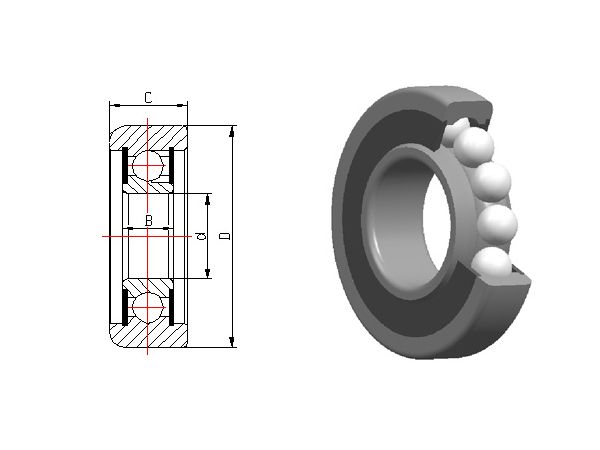

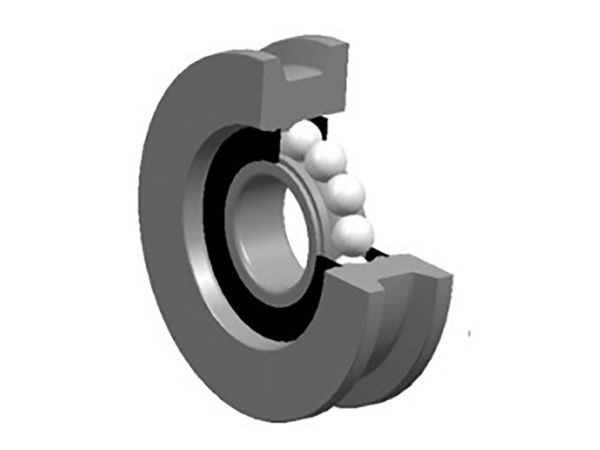

Single Row Full Complement Ball Bearing Mast Guide BearingsPlease download the PDF for details.

Single Row Full Complement Ball Bearing Mast Guide BearingsPlease download the PDF for details. -

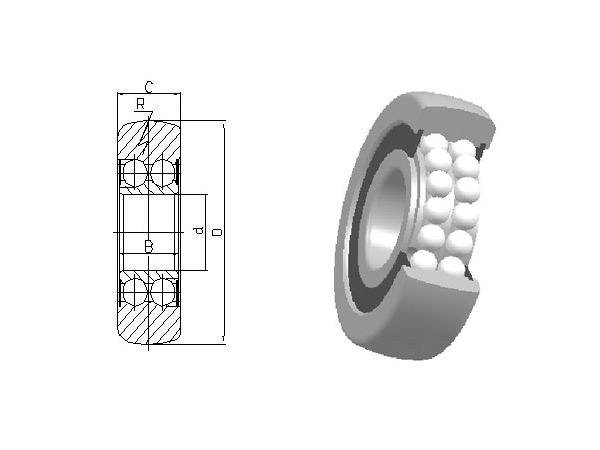

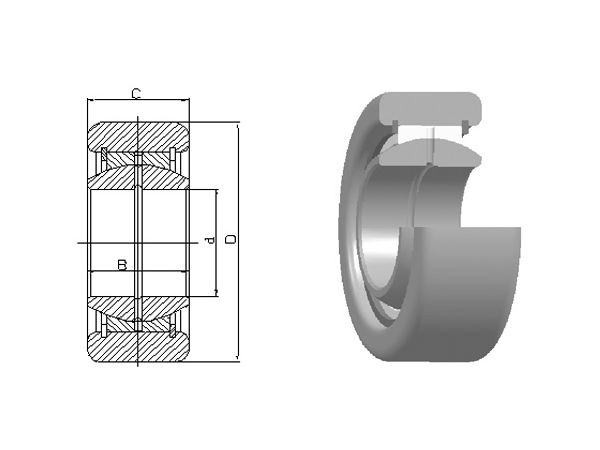

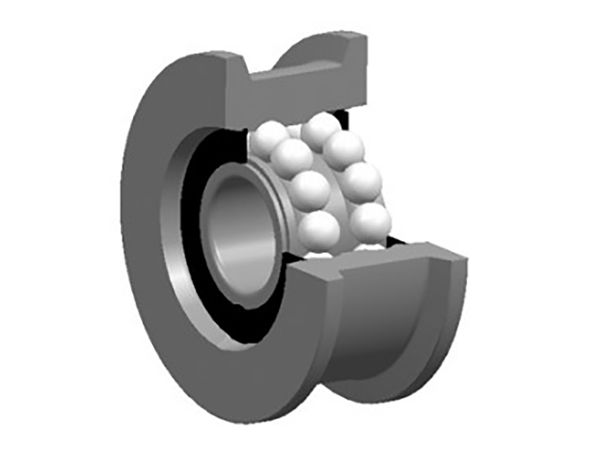

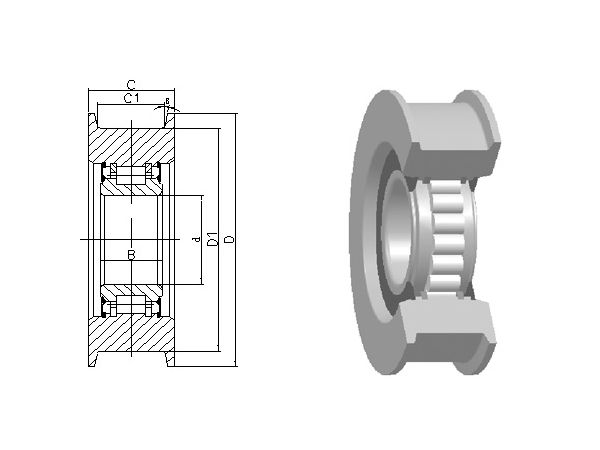

Double Row Full Complement Ball Bearing Mast Guide BearingsPlease download the PDF for details.

Double Row Full Complement Ball Bearing Mast Guide BearingsPlease download the PDF for details. -

Single Row Ball Bearing Mast Guide BearingsPlease download the PDF for details.

Single Row Ball Bearing Mast Guide BearingsPlease download the PDF for details. -

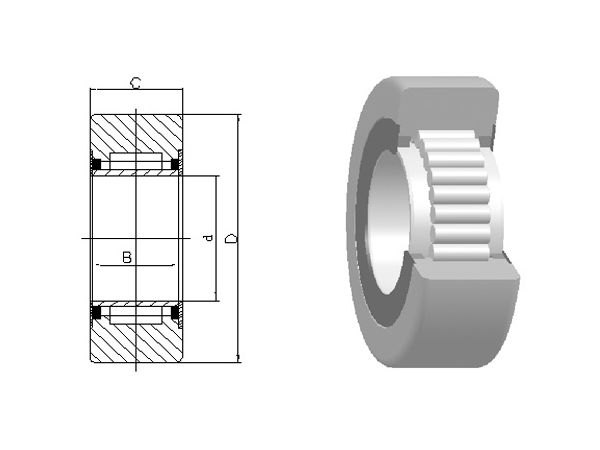

Needle Roller Bearing Mast Guide BearingsPlease download the PDF for details.

Needle Roller Bearing Mast Guide BearingsPlease download the PDF for details. -

Spherical Roller Bearing Mast Guide BearingsPlease download the PDF for details.

Spherical Roller Bearing Mast Guide BearingsPlease download the PDF for details. -

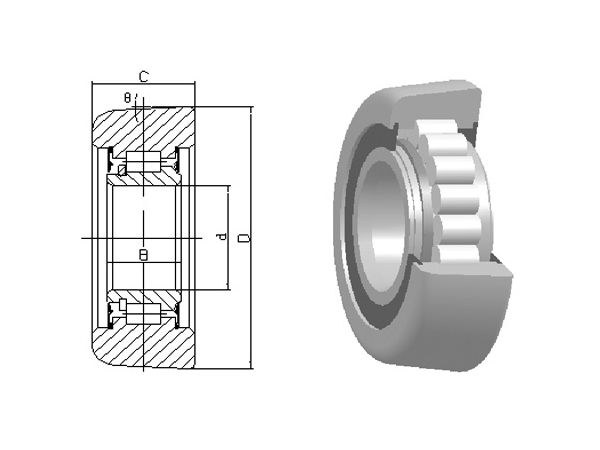

Single Row Roller Bearing Mast Guide BearingsPlease download the PDF for details.

Single Row Roller Bearing Mast Guide BearingsPlease download the PDF for details.

-

Single Row Ball Bearing Chain SheavesPlease download the PDF for details.

Single Row Ball Bearing Chain SheavesPlease download the PDF for details. -

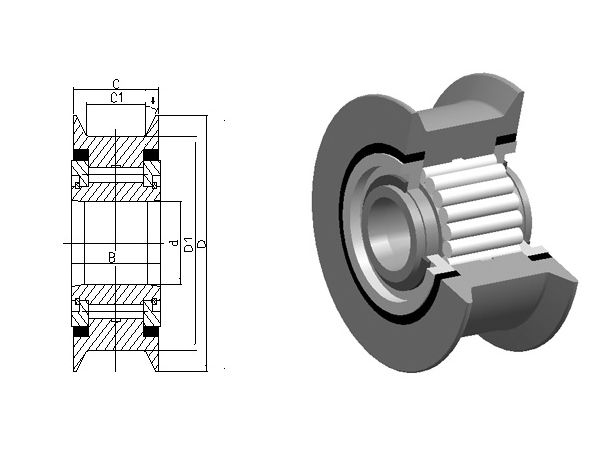

Double Row Ball Bearing Chain SheavesPlease download the PDF for details.

Double Row Ball Bearing Chain SheavesPlease download the PDF for details. -

Single Row Full Complement Ball Bearing Chain SheavesPlease download the PDF for details.

Single Row Full Complement Ball Bearing Chain SheavesPlease download the PDF for details. -

Double Row Full Complement Ball Bearing Chain SheavesPlease download the PDF for details.

Double Row Full Complement Ball Bearing Chain SheavesPlease download the PDF for details. -

Single Row Ball Bearing Chain SheavesPlease download the PDF for details.

Single Row Ball Bearing Chain SheavesPlease download the PDF for details. -

Needle Roller Bearing Chain SheavesPlease download the PDF for details.

Needle Roller Bearing Chain SheavesPlease download the PDF for details. -

Single Row Roller Bearing Chain SheavesPlease download the PDF for details.

Single Row Roller Bearing Chain SheavesPlease download the PDF for details.

What are the common bearing lubrication methods?

In industrial bearings, the most common lubrication methods are:

- Oil lubricants

- Grease lubricants

How to select the right bearing lubrication methods?

| Lubricant | Grease | Oil |

| Speed suitability (n * dm) | *** Approx. 2mm | ***** Approx. 3 to 4mm |

| Service life | *** | ***** |

| Design / system costs | ***** (low) | * (higher) |

| Operating costs | ***** (low) | * (higher) |

| Heat dissipation | ** | **** |

| Running in procedure | ** | *** |

| Pollution | ***** (low) | * (higher) |

*****: very good

*: poor

What are rolling bearings and why are they important?

Rolling bearings are mechanical components designed to reduce friction between moving parts and facilitate smooth motion in machinery. Unlike sliding bearings, rolling bearings use cylindrical, needle, or tapered rollers to carry and distribute loads. This rolling action minimizes friction, heat, and wear, making rolling bearings crucial for efficient operation across various industrial applications.