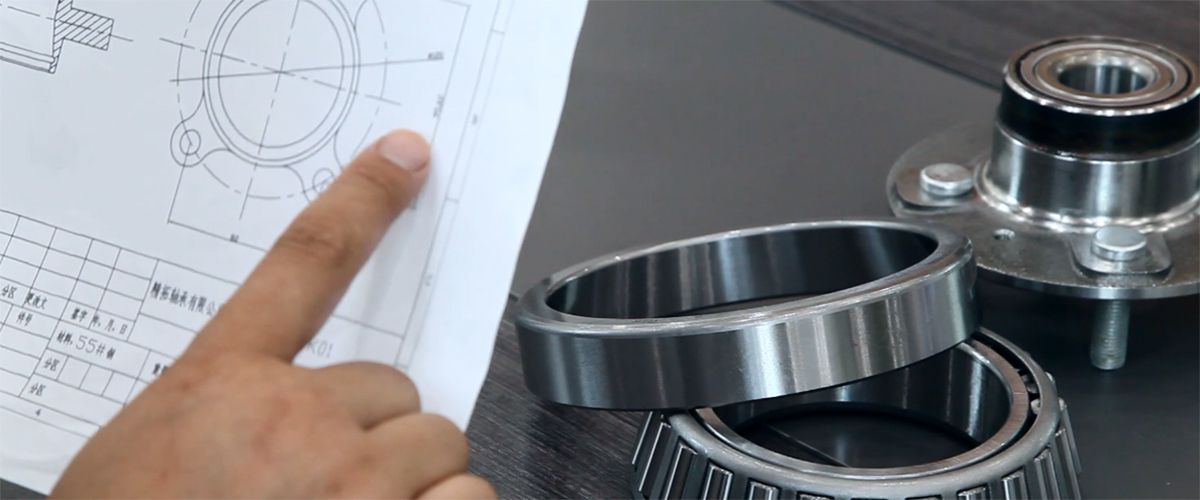

JITO can customize and design special bearings to address operational environment challenges, extend lifespan, enhance equipment performance, and even save energy.

- If the customer provides drawings with dimensions, materials, and special requirements, we can create molds based on those drawings.

- If the customer does not have drawings, we can design according to their requirements, create drawings, and obtain customer approval. Then we proceed to mold production. We prepare the molds for shipment and send samples to the customer for approval before shipment.

- After the trial mold, we ensure its normal functioning. Then we produce samples. Our engineers will measure and confirm the samples. We will then prepare the documentation and arrange shipment to the customer, sometimes by air if urgent.

- Bearing dimensions (inner diameter, outer diameter, height)

- Bearing material

- Specific features or performance of the bearing

Bearings are mechanical components that play a central role in almost all applications involving rotating parts. Nearly every engineer encounters this topic at some point in their career and faces the tasks of design, sizing, and correctly integrating rolling bearings into machines. If you aim to master these skills through self-study, the necessary accumulation is a lengthy process. In today's business world, almost no company is not efficiently utilizing increasingly compressed development times, nor can any company afford design errors due to lack of expertise.

In addition to providing fundamental knowledge of rolling bearing technology, our company also offers rapid and comprehensive training in the specialized knowledge of rolling bearing manufacturers. We offer flexible training options, available either on-site at your company or at our facilities.

Participants have the opportunity to gain deeper insights into our rolling bearing production processes and learn more about our company. Depending on the number and qualifications of participants, we can arrange training sessions spanning one or several days. We are committed to assisting you in organizing and conducting these sessions. Our training materials are customized to meet your specific needs, and we always incorporate practical, illustrative materials to enhance learning experiences.

The assembly of bearings is always a critical issue, as the first thing considered when a bearing fail is whether it was correctly installed. This is not surprising, as potential damage caused during the installation or handling process of rolling bearings is the second most common reason for premature bearing failure after lubrication.

Especially heavy-duty and large rolling bearings are more challenging to install, and they may suffer early failures due to carelessness, improper transportation, or errors during the assembly process. The cost of a single special repair is high, not to mention the downtime cost and pressure on affected systems.

Our engineers provide recommendations in advance for bearing installation, assisting in avoiding initial errors, recommending the best assembly strategies, and providing on-site advice and support.