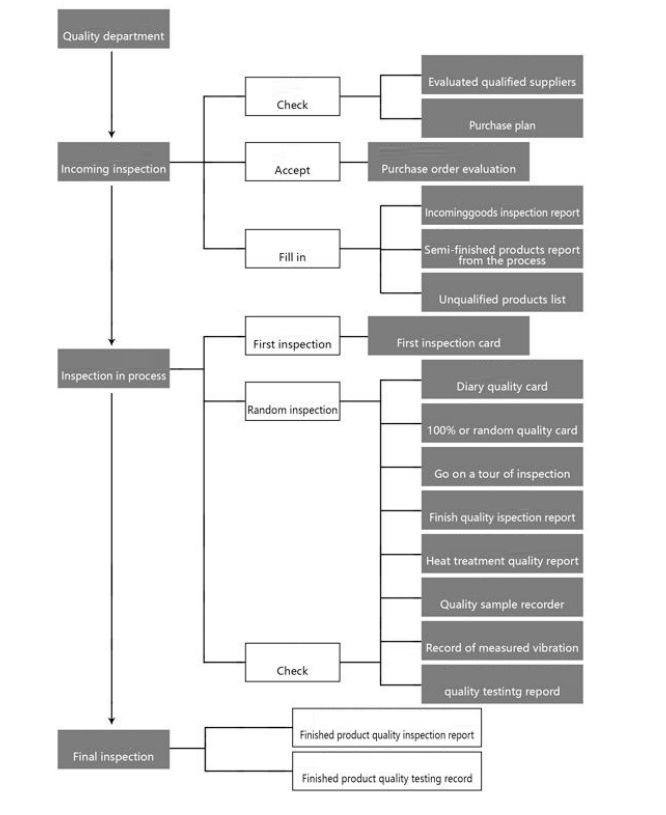

JITO adheres to the principle of "pursuing excellence," ensuring rigorous product inspection processes at every stage of production, from raw material procurement, forging, machining, and heat treatment, to grinding, quality inspection, automated assembly, cleaning, oiling, and packaging for shipment. This ensures that the performance of our product meet international standards. The specific process is outlined as follows:

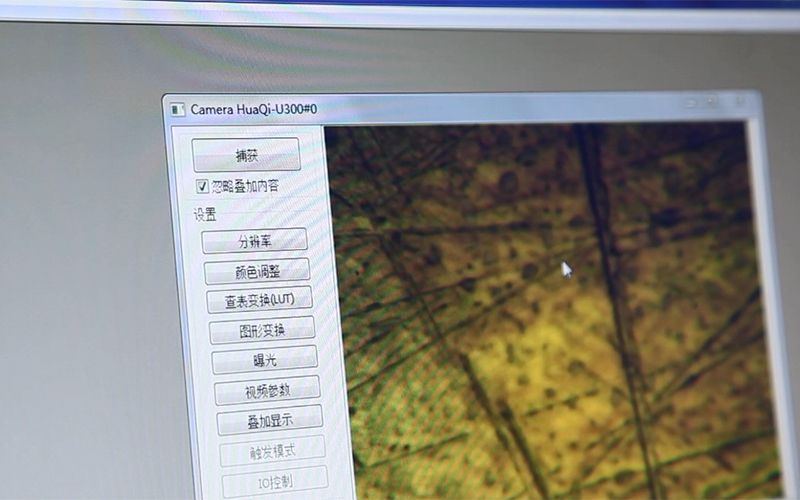

Our company has established an advanced R&D and testing center, equipped with state-of-the-art testing instruments, including coordinate measuring machines, universal length measuring systems, spectrometers, profile measuring machines, cylindricity measuring instruments, vibration meters, hardness testers, metallographic microscopes, bearing fatigue testing machines, and various other measurement instruments. These instruments are utilized for comprehensive quality control throughout the entire production process, thoroughly inspecting the comprehensive performance of products to ensure zero defects in JITO products.

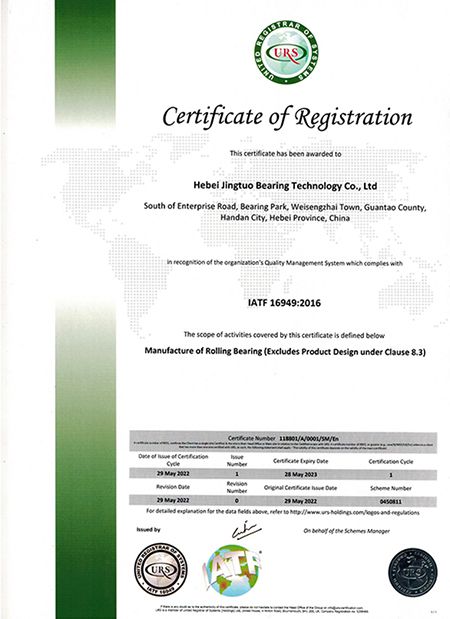

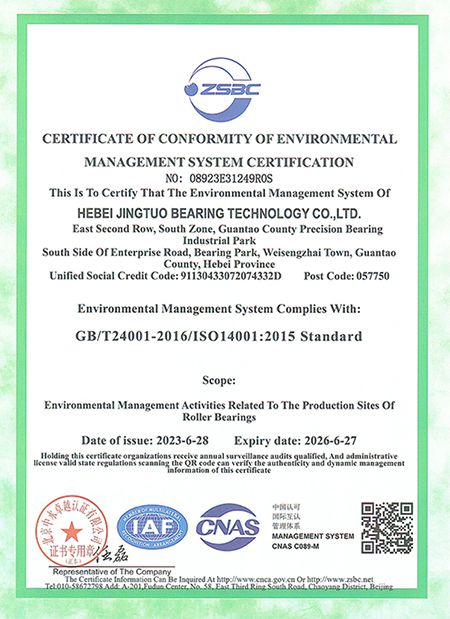

Our company has successively obtained ISO 9001 and IATF/16949 quality management system certifications. In 2016, the JITO brand was officially registered in the European Union. The exceptional product quality has enabled us to penetrate markets in over 30 countries worldwide. Moreover, we have established strategic partnerships with numerous esteemed brands from diverse countries.