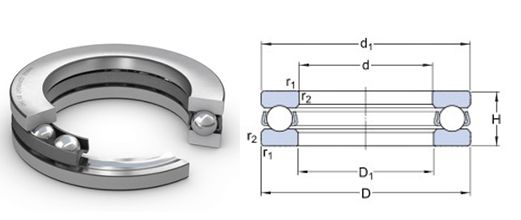

Single Direction Thrust Ball Bearings

Single direction thrust ball bearings consist of spherical rollers and two bearing washers, with one bearing washer designed with grooves to accommodate the rollers, while the other bearing housing is flat. This type of bearing can withstand thrust loads from one direction, while its load capacity in the other direction is relatively low.

These ball bearings are characterized by simple structure, easy installation, and reliable operation. Single direction thrust ball bearings are typically made of steel or chromium-molybdenum alloy steel, offering high load capacity and fatigue resistance. They are suitable for high speed operations with limited space.

Specifications- Material: Chrome steel, stainless steel, ceramic hybrid, plastic

- Precision: ABEC-1 to ABEC-9

- Size: Greater than or equal to 2mm bore dia.

- Cage: Stamped steel cage, solid cage

Single direction thrust ball bearings are commonly used in various mechanical equipment such as automotive transmission systems, aerospace equipment, and construction machinery to provide support and stability in the axial direction.

Will heat treatment affect the quality of the bearings I purchase?

Yes, the thickness of the steel will affect the heating time, and bearings of the same size and thickness need to be heated together. Many outsourced heat treatment plants, in order to save time, heat steel of different thicknesses together in the same batch, which can result in uneven heating of the steel and reduce durability. However, we have our own heat treatment plant to clearly control each batch of bearings of different sizes and thicknesses, ensuring that the bearings achieve the optimal hardness and toughness.

How can I prevent bearings from rusting?

Choose bearings made of materials coated with zinc or tin. Also, wear gloves when installing bearings. If there is direct contact with the bearings by hand, remember to apply rust preventive oil after installation. If you want to completely avoid rust, you can also choose stainless steel or ceramic bearing materials.

What do the bearing clearance designations C0, C2, C3, C4, and C5 signify?

The selection of proper bearing clearance is critical as it directly impacts the function and longevity of the bearing. ISO standards have defined five clearance classes for various types of bearings, which are as follows:

- C2: Smaller than normal clearance

- C0: Normal clearance

- C3: Greater than normal clearance

- C4: Greater than C3 clearance

- C5: Greater than C4 clearance